Depending on the purpose of usage, such as drinking water, household water, or industrial water, the quality of clean water must be assured in accordance with different requirements, assuring the quality of water after treatment. fulfill the specifications for each planned usage

Water that has been treated and cleaned using contemporary technology at water plants is known as clean water, also known as supply water. Following that, water is transported to transfer stations via a pipeline system in order to be distributed to customers.

In most cases, water supply is categorized based on factors such as:

Classification by input water source:

– Underground water source: well water, …

Surface water sources: rivers, streams, ponds, lakes, etc.

Classification by purpose of use:

– Water supply for drinking purposes (standard QCVN 01:2009/BYT)

– Water supply for domestic use (standard QCVN 02:2009/BYT)

– Water used for production

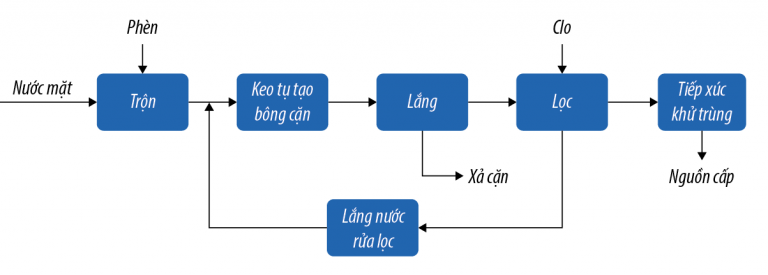

Surface water treatment process

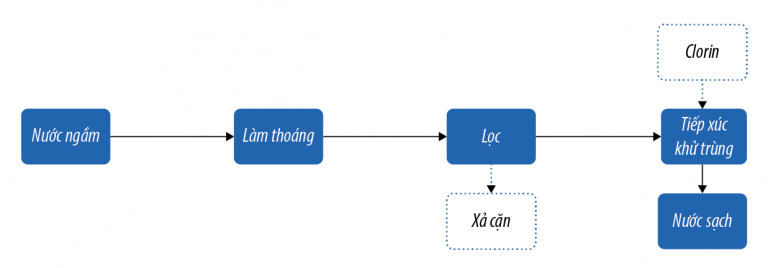

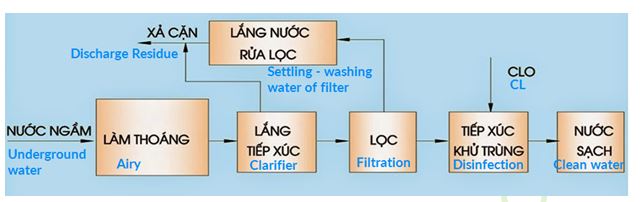

Groundwater treatment process

The use of mechanical or physico-chemical techniques to eliminate pollutants contained in water from various sources such as groundwater and surface water are features of feed water treatment technology.

This method uses equipment for storage and pre-settlement, garbage screens, garbage screens, settling tanks, and filter tanks. Follow this step-by-step sequence:

– Reservoir creation and pre-settlement

– Reduce suspended sediments

– Set up barricades and garbage nets:

Barriers and nets are set at the entry to the collection work, which is responsible for removing floating items and floating objects in the water stream, therefore protecting equipment and improving treatment plant cleaning efficiency. water.

– Create sand settling tank:

The purpose of the sand settling tank is to produce favorable circumstances for settling big particles in order to decrease the quantity of heavy sediment that accumulates in the flocculation tank and settling tank, as well as to reduce mechanical moving mechanism wear.

– Create a settling tank:

Before pouring water into the filter tank, the settling tank is responsible for preliminary cleaning, which helps to complete the domestication process. Horizontal clarifiers, vertical clarifiers, thin layer clarifiers, and clear clarifiers with suspended sediment are the different types of settling tanks based on the flow direction.

– Filter part:

Filter tank and filter mechanism with screening function to totally separate solid particles in water are included. It is not essential to employ high-pressure filtering equipment for large-capacity water treatment systems, but rather filter tanks containing granular filter materials such as quartz sand, coke, crushed gravel…. Slow filters, rapid filters, open filters, and closed filters are the four types of particle layer filters.

Basic water treatment technology

According to the mechanism, the following is the method of operation: Use alum to coagulate the water, lime to alkalize it, and chlorine to disinfect it. The steps are as follows:

– Clearing:

The aeration process raises the water’s dissolved oxygen concentration, boosting the redox potential and facilitating the oxidation of organic compounds in the deodorizing and odorizing process. Effective:

– Pre-chlorination:

Pre-chlorination is the process of adding chlorine to the water before the clarifier and filter. Pre-chlorination has the following effects:

– Chemical mixing process:

Helps to quickly and evenly disperse alum and other chemicals into the water to be treated.

– Coagulation – Forming cotton:

The goal of the flocculation and floc creation processes is to generate an agent that can bind dissolved water pollutants in suspended form into flocs that can settle in settling tanks and bind on the surface. at the fastest and most cost-effective pace possible on the particle surface of the filter medium layer

When alum is mixed with treated water, chemical and physical-chemical interactions begin almost instantly, generating a positive colloidal system that is equally diffused in water. Once neutralized, this positive colloidal system becomes the nucleus capable of associating with other substances. In water, negative colloids scatter and stay together to create floc. As a result, agglomeration is known as flocculation, and the reaction between agglomeration and flocculation is known as flocculation reaction.

– Settling process:

Reduces the number of germs and bacteria in the water by removing particles and flocs that can settle at a reasonable rate.

– Filtering process:

Small particles that do not settle in the clarifier but have the potential to adhere to the filter’s surface are removed.

– Absorption and adsorption by activated carbon:

Traditional treatment procedures do not provide sufficient deodorization, taste, or color of water.

– Water fluoridation:

Raise the fluorine content in water to 0.6 – 0.9 mg/l to protect tooth enamel and bones for water users.

– Disinfection of water:

Water disinfection is a necessary part of the drinking water treatment process. The majority of bacteria are maintained following mechanical feed water treatment operations, particularly after passing through the filter tank, however disinfection is required to entirely eradicate harmful bacteria. There are several effective sterilization procedures available today, including those using powerful oxidizing chemicals, physical rays, ultrasonic, thermal methods, heavy metal ions, and so forth.

– Water stabilization:

Eliminates cavitation and creates an isolating protective film that does not allow water to come into direct contact with the inner surface of the pipe wall to protect the pipe and its fittings.

– Water softeners:

Reduce from water Ca2+ and Mg2+ ions to the required concentration.

– Desalination:

Reduce from water the cations and anions of the dissolved salts to the required concentration.

Clean water treatment plant in Yen My II industrial zone, phase 1 by Ecoba ENT as the main contractor

In addition to the therapeutic options listed above. The following procedures are employed in the treatment of feed water when the quality of the source water is higher:

– Air fresheners, powerful oxidizing agents, and activated carbon are used to deodorize smells and tastes.

– Heat, chemical, and ion-exchange methods are all used to soften water.

– Ion exchange, electrolysis, membrane filtration, heat, or distillation are all methods for desalinating water.

<Video>

Flycam of clean water treatment plant Yen My Industrial Park II

Application of water treatment technology

– Making clean water for residential use.

– Raw water used in the culinary, pharmaceutical, beverage, and beer sectors to process technologically sophisticated water.

Ecoba Environmental Technology Co., Ltd (Ecoba ENT) is Vietnam’s most recognized and professional water treatment contractor. Understanding the importance of water in life and productivity, Ecoba ENT constantly develops exceptional solutions for each project, using contemporary technology and the most competent service to bring clients. pure water of the highest quality, meeting user health and safety requirements, and servicing the production and commercial processes

Ecoba ENT has completed numerous water treatment projects, including a clean water treatment system for a slaughterhouse and a meat processing factory in Hanoi, a clean water treatment plant in Phu Vinh Industrial Park, a clean water treatment station in Yen My II Industrial Park, phase 1 and a clean water treatment station in Nam Son Hap Linh Industrial Park….

Customers interested in seeing clean water treatment plants or receiving environmental advice should call the hotline at 0901 68 77 88 – 08 8899 0789 – 08 9966 0789.